Brinell hardness testing gives value of hardness of materials

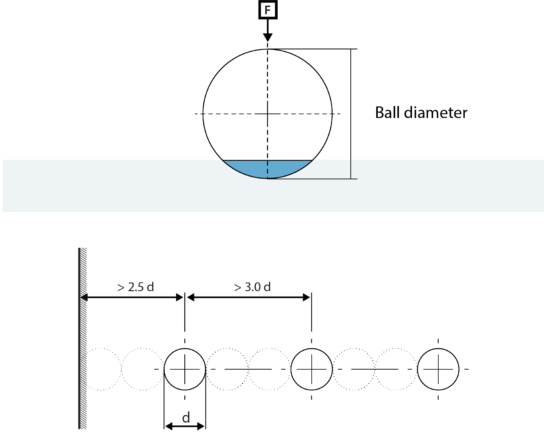

Sometimes the material is too rough or too coarse to be tested. Brinell hardness testing is often used to determine the hardness of castings with a grain structure too course for Rockwell or Vickers testing for instance and then Brinell is used as harder materials are important to the industry. A metal ball acts as an indenter and a force is applied on the ball to produce the indentation. The actual hardness of the material is determined by the resistance it puts up to another material penetrating its surface. The harder the material the higher its strength.

Measuring the resistance of the material

Brinell hardness testing, devised by Swedish born metallurgist, works for lots of different materials. You could say the benefits of the test is that it determines the hardness of lots of materials while being easy to carry out. The indenter is pressed into the material by an accurately controlled test force that is maintained for a time of about 10 – 15 seconds, giving you the exact value of the hardness of heterogeneous materials. After the time has lapsed, the indenter is removed and an indent is left. Brinell tests are frequently done on large parts and if you vary the ball size and test force, just about all metals can be tested. There are other tests for hardness but common indentation hardness scales are Brinell.